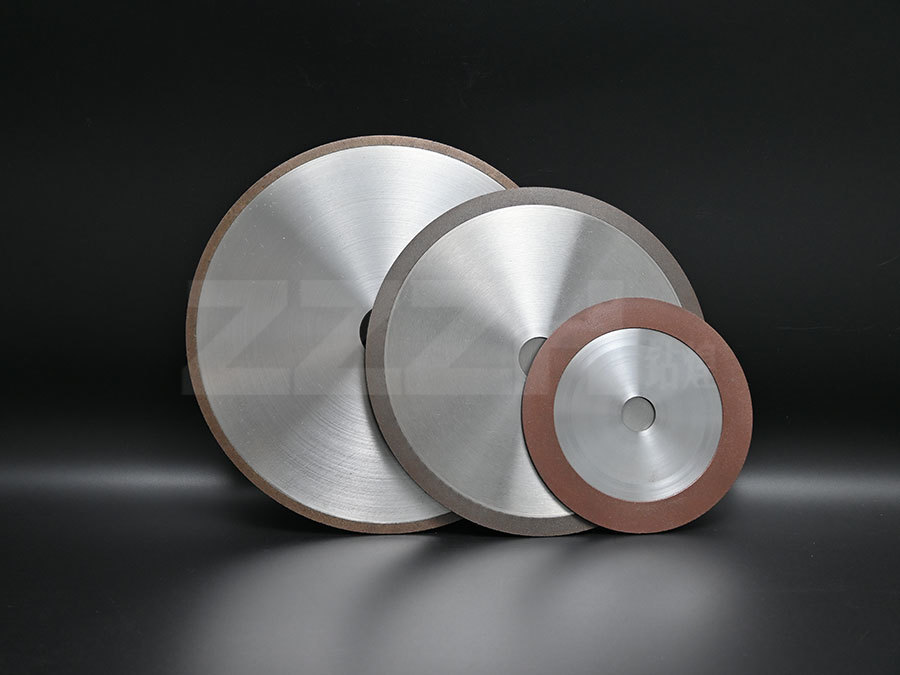

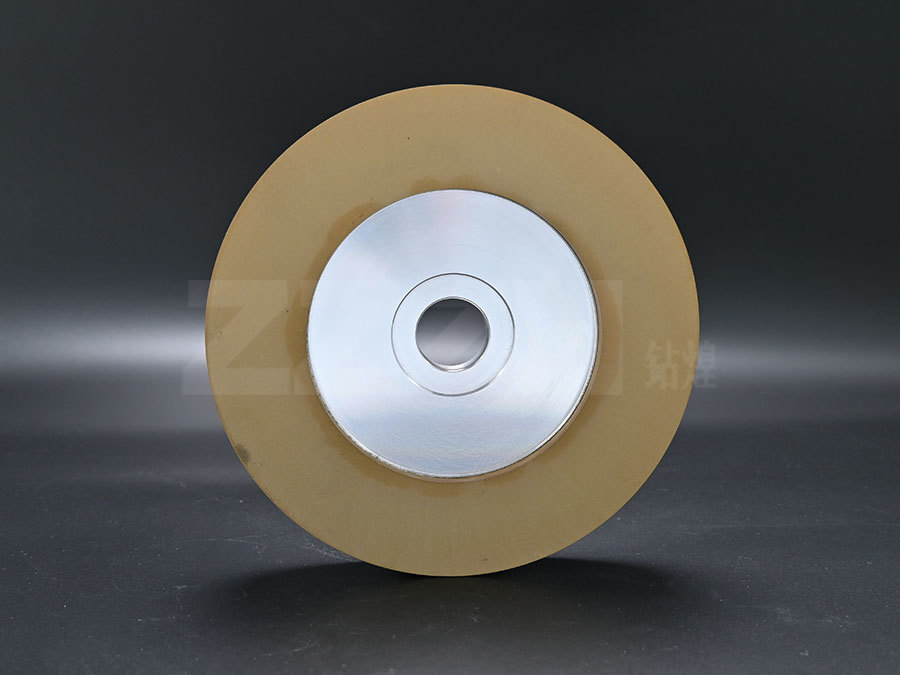

Resin Diamond Grinding Wheel

I. Introduction

In the field of grinding processing, resin diamond grinding wheels have become one of the indispensable tools due to their unique performance and wide range of applications. As a type of abrasive tool that combines resin binders and diamond abrasives, resin diamond grinding wheels exhibit significant advantages in hardness, wear resistance, processing efficiency, and applicability. This article will delve into the basic composition, manufacturing process, performance characteristics, and applications of resin diamond grinding wheels in various industrial fields, aiming to provide readers with a comprehensive and in-depth understanding.

II. Basic Composition of Resin Diamond Grinding Wheels

Resin diamond grinding wheels are mainly composed of diamond abrasives, resin binders, reinforcing materials, and fillers. Diamond abrasives, with their extremely high hardness and wear resistance, are responsible for the actual grinding work; resin binders serve to firmly bond the abrasives together while providing the wheel with a certain degree of elasticity and self-sharpening; reinforcing materials such as fiberglass and carbon fiber are used to enhance the strength and toughness of the wheel; fillers are used to adjust the porosity of the wheel, affecting the cooling effect and chip removal capability during grinding.

III. Manufacturing Process

The manufacturing process of resin diamond grinding wheels can be roughly divided into several key steps: raw material preparation, mixing and stirring, molding and curing, and trimming and inspection. First, select suitable diamond abrasives, resin binders, and other auxiliary materials according to the usage requirements, and accurately weigh them in a certain proportion. Then, mix them thoroughly in mixing equipment to ensure uniform dispersion of all components. Next, inject the mixed materials into molds, and eliminate bubbles through pressure or vacuum treatment to form a grinding wheel blank of the desired shape. After that, place the blank in an oven for heating and curing, allowing the resin binder to undergo a chemical reaction to firmly bond the abrasives. Finally, trim the cured wheel to remove burrs, check dimensional accuracy and surface quality, ensuring the product meets usage standards.

IV. Performance Characteristics

1. High hardness and wear resistance: Diamond, being one of the hardest substances in nature, allows resin diamond grinding wheels to exhibit extremely high efficiency and durability when grinding hard materials.

2. Good self-sharpening: The resin binder gradually wears down during the grinding process, exposing new abrasive particles, maintaining the sharpness of the wheel, and reducing grinding force and heat accumulation.

3. Good elasticity and strong adaptability: The resin binder provides the wheel with a certain degree of elasticity, allowing it to better conform to the surface of the workpiece, making it suitable for grinding complex-shaped workpieces.

4. High processing precision: Through fine manufacturing processes, resin diamond grinding wheels can provide high-precision grinding surfaces, meeting the needs of precision machining.

5. Easy to trim and maintain: Compared to other types of grinding wheels, resin diamond grinding wheels are easier to trim, maintaining their good grinding performance.

V. Applications

Due to their excellent performance, resin diamond grinding wheels are widely used in various industrial fields. In the processing of high-hardness materials such as optical glass, ceramics, hard alloys, and semiconductor materials, resin diamond grinding wheels can provide efficient and precise grinding solutions. Additionally, in industries such as automotive manufacturing, aerospace, and medical devices, the efficient processing of precision parts also relies on the support of resin diamond grinding wheels. With the continuous advancement of technology, the application range of resin diamond grinding wheels is also expanding, showing unique advantages in areas such as post-processing of 3D printing and composite material processing.

VI. Conclusion

In summary, resin diamond grinding wheels play a crucial role in modern manufacturing due to their excellent performance characteristics and wide range of applications. With the continuous development of materials science and manufacturing technology, the performance of resin diamond grinding wheels will further improve, and their application fields will become even broader. For professionals in related industries, a deep understanding of the basic principles, manufacturing processes, and application characteristics of resin diamond grinding wheels is not only helpful in improving processing efficiency and product quality but is also key to promoting technological innovation and industrial upgrading.

Providing high-quality cutting blades for numerous industries!

We are committed to providing the best service to our customers.

★Our sales team has professional product knowledge and rich application experience. They are optimistic and enthusiastic and provide you with the most attentive service.

★No matter what questions you have about our products after receiving the goods, our after-sales service team will patiently answer for you and solve the problem for you in time.

Factory strength

The factory and office area is approximately 6000 square meters, with over 50 imported equipment. Having a large and stable inventory, it can meet the wholesale needs of customers in large quantities.

R & D strength

We have a mature R&D and design team with 8 years of production and sales experience. Our mold design is updated quickly, and we maintain the monthly launch of 1 to 2 new products, leading the market in new trends.

Custom strength

Continuously developing new processes, introducing new technologies, designing and customizing various personalized accessories for customers, ensuring product shipment within one month.

After-sales service

Dedicated customer service is available 24 hours a day, providing attentive service in the first place. Customers establish customer documents and regularly follow up on product usage. We serve every customer with care.

Resin diamond grinding wheel

Key words:

Resin diamond grinding wheel

Classification:

Related recommend

The company provides high-quality cutting discs for precision groove grinding, grooving, cutting, and single and multi-round cutting operations in a wide range of industries worldwide.

Service Hotline:

Fax:+860371-67126889

Email:zhcycl@163.com

Address:167 Xuchang Road, Shangjie District, Zhengzhou City

WeChat QR Code

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSSWE-ZQF

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page