1. Definition and Function of Metallographic Cutting Discs

FunctionA precision cutting tool specifically designed for metallographic sample preparation, cutting through metals, ceramics, and other materials at high speeds,Retaining the original microstructure of the sample, avoiding thermal damage or deformation.

Core Requirements:

High Cutting Precision: Ensuring a smooth cut, reducing subsequent grinding workload

Low Thermal Impact: Preventing high temperatures from altering the material's microstructure

Cleanliness: Avoiding contamination of the sample by cutting debris

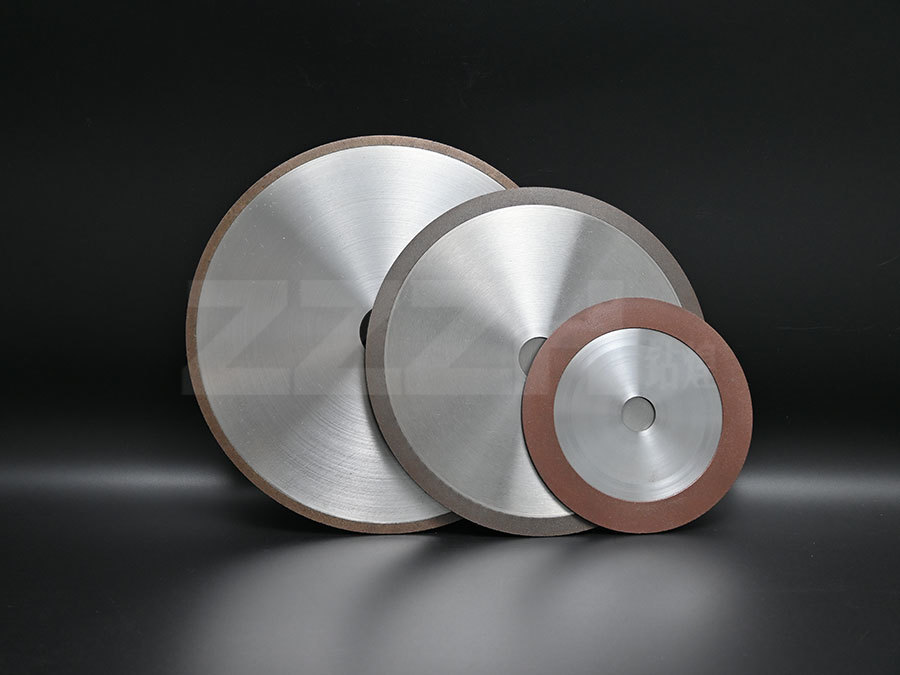

2. Cutting Disc Materials and Classification

Type |

Material/Structure |

Applicable Scenarios |

Advantages |

Limitations |

|---|---|---|---|---|

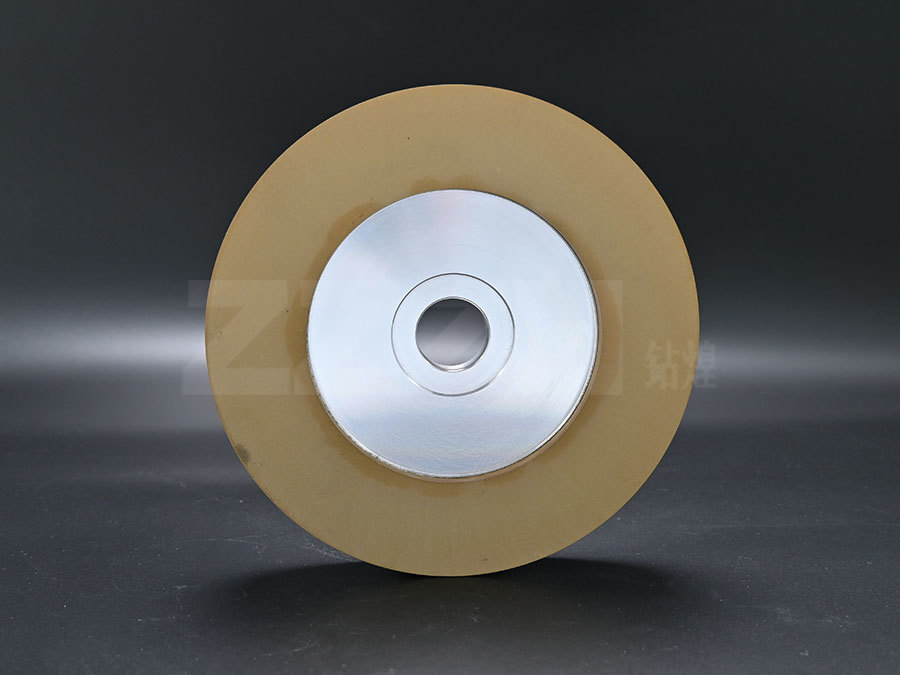

Resin Bond |

Diamond + Resin Bonding |

Hard and Brittle Materials (Glass, Hardened Steel) |

Elastic cushioning, good heat dissipation, smooth cutting surface |

Short lifespan, not heat resistant |

Metal Bond |

Diamond Abrasive + Metal Matrix |

Superhard Materials (Ceramics, Titanium Alloys) |

Strong wear resistance, long lifespan |

Slow cutting speed |

3. Key Performance Parameters

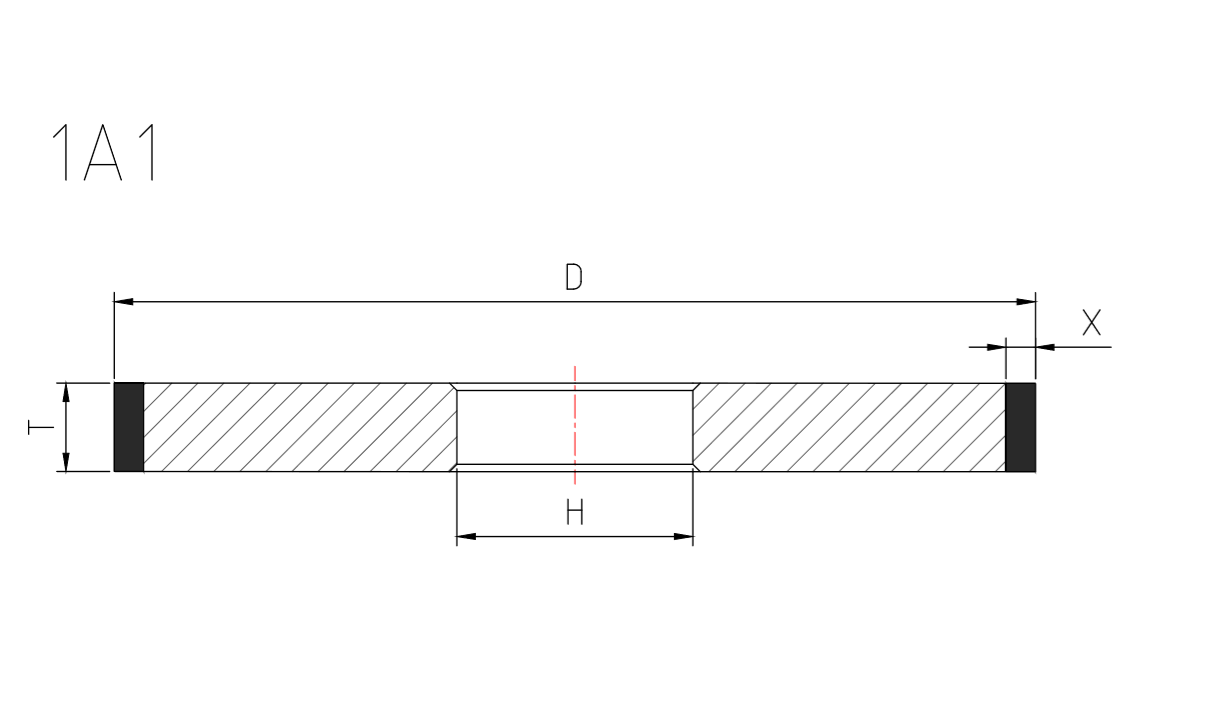

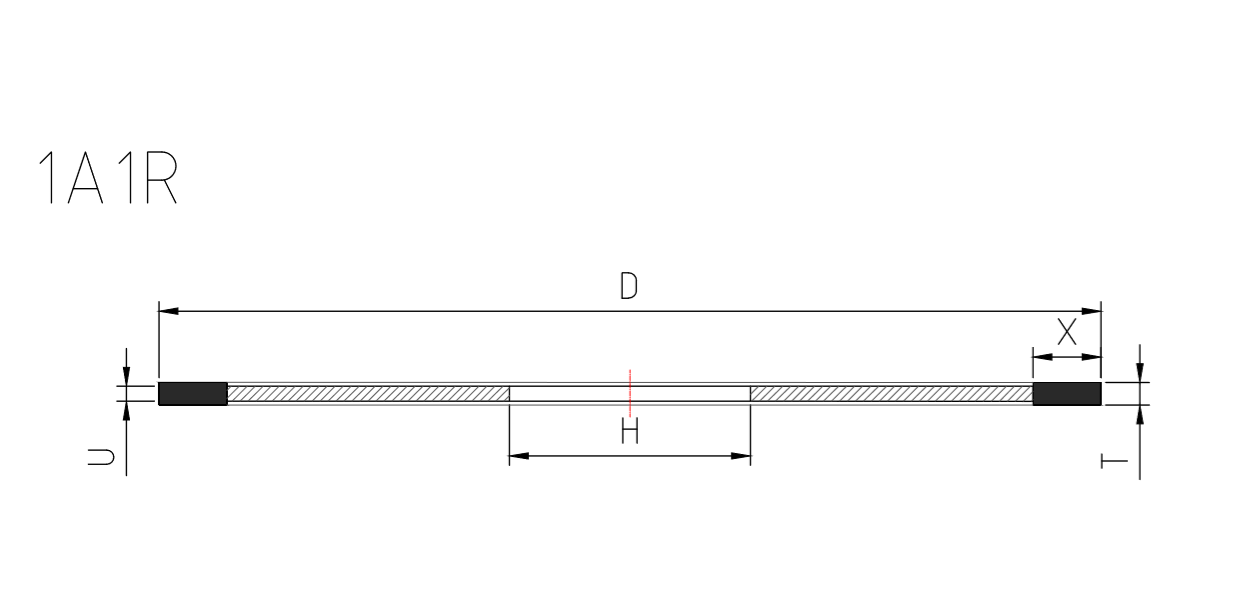

Outer Diameter and Thickness: Common outer diameters are 100-350mm, thicknesses of 0.5-3mm (thin discs for precision cutting)

Abrasive Grain Size:

Coarse Grain Size (80-120 mesh): Fast cutting, suitable for large samples

Fine Grain Size (200-400 mesh): High precision cutting, reduces subsequent polishing

Maximum Rotational Speed: Must match the rated speed of the cutting machine (usually marked as m/s or RPM)

4. Selection Guide

Choose Based on Material Hardness:

Soft Metals (Aluminum, Copper) → Silicon Carbide Cutting Discs

High Hard Materials (High-Speed Steel, Ceramics) → Diamond Cutting Discs

Choose Based on Cutting Requirements:

Routine Testing → Resin Bonding offers high cost-performance ratio

High Precision Research → Electroplated Ultra-Thin Cutting Discs

5. Usage Precautions

Coolant is Essential: Use water-based or oil-based coolants to lower temperature, preventing sample oxidation and overheating of the cutting disc

Cutting Parameters:

Feed Speed: Slow for hard materials (0.01-0.1mm/s), can be increased for soft materials

Cutting Pressure: Light and gradual, avoiding impact loads

Safety Protection: Wear safety goggles and dust masks, ensure the equipment's protective cover is intact

6. Common Problems and Solutions

Problem Phenomenon |

Possible Causes |

Solutions |

|---|---|---|

Burning of Cutting Surface |

Insufficient cooling or excessive speed |

Increase coolant flow, reduce speed |

Abnormal Wear of Cutting Disc |

Mismatch between material and cutting disc |

Replace with a cutting disc of higher hardness/bonding agent |

Sample Edge Chipping |

Feed speed too fast or unstable clamping |

Reduce feed amount, use specialized fixtures to secure the sample |

Providing high-quality cutting blades for numerous industries!

We are committed to providing the best service to our customers.

★Our sales team has professional product knowledge and rich application experience. They are optimistic and enthusiastic and provide you with the most attentive service.

★No matter what questions you have about our products after receiving the goods, our after-sales service team will patiently answer for you and solve the problem for you in time.

Factory strength

The factory and office area is approximately 6000 square meters, with over 50 imported equipment. Having a large and stable inventory, it can meet the wholesale needs of customers in large quantities.

R & D strength

We have a mature R&D and design team with 8 years of production and sales experience. Our mold design is updated quickly, and we maintain the monthly launch of 1 to 2 new products, leading the market in new trends.

Custom strength

Continuously developing new processes, introducing new technologies, designing and customizing various personalized accessories for customers, ensuring product shipment within one month.

After-sales service

Dedicated customer service is available 24 hours a day, providing attentive service in the first place. Customers establish customer documents and regularly follow up on product usage. We serve every customer with care.

Metallographic cutting disc

Key words:

Metallographic cutting disc

Classification:

Related recommend

The company provides high-quality cutting discs for precision groove grinding, grooving, cutting, and single and multi-round cutting operations in a wide range of industries worldwide.

Service Hotline:

Fax:+860371-67126889

Email:zhcycl@163.com

Address:167 Xuchang Road, Shangjie District, Zhengzhou City

WeChat QR Code

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSSWE-ZQF

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page